Bender

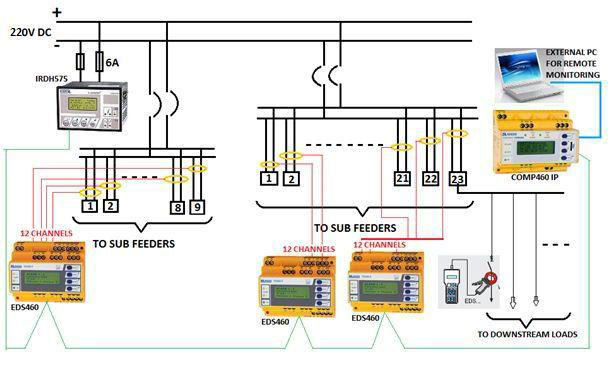

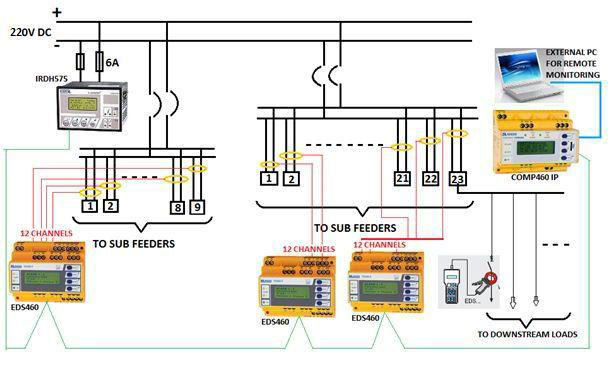

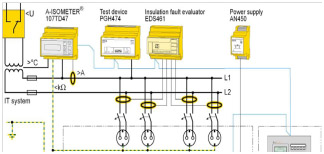

Electrical insulation is one of the critical components of any electrical system, the condition of which determines the reliability, availability and integrity of complete electrical & instrumentation system. Monitoring of insulation resistance and localization of 1st earth fault is essential in order to ensure maximum safety and availability of ungrounded power distribution system (IT System).

|

• The insulation measurement is done via active measurement principle which employs injection of special bender patented AMPPLUS pulse

• The insulation monitor will measure the insulation resistance of complete galvanically connected system in real time and display its value in the backlit LC display. • Response values from 1 KΩ to 10 MΩ. • Nominal System Voltage AC,Dc or AC/DC up to 7.2 KV. • System Leakage capacitance up to 500 µF. • System Configurations 1Ph, 3Ph, disconnected loads. • Automatic Fault location with faulty feeder. • Automatically adapts to the system conditions and eliminates the effects of factors affecting accurate measurement such as Extraneous DC voltages, high and variable system leakage capacitances, variable low frequencies, harmonics etc. • Displaying information about the status of the electrical installation at a central location. • Remote diagnosis via internet/Ethernet. • All the Bender devices are in conformance to IEC 61557-8 and IEC 61557-9 and EMC qualified as per IEC 61326-2-4. |

Applications:

• Ungrounded PV Solar Plants

• Insulation/earth fault monitoring in all Ungrounded Power supplies particularly in 48V/220V DCDBs in Power Generations/transmission/distribution.

• Ungrounded AC/DC VFD drives, PLC and SCADA applications, paper industries, rolling mills etc.

• Ungrounded 24V/48V/110V/220V in Oil Gas Plants/Petrochemical Industries.

• Offline Insulation Monitoring of standby loads, high voltage motors.

• Ungrounded power distribution in ships and offshore vessels.

• Ungrounded generator excitation system, rotor earth fault monitoring, ungrounded wind turbines etc.

• System is recommended according to IEC60364-4-41.

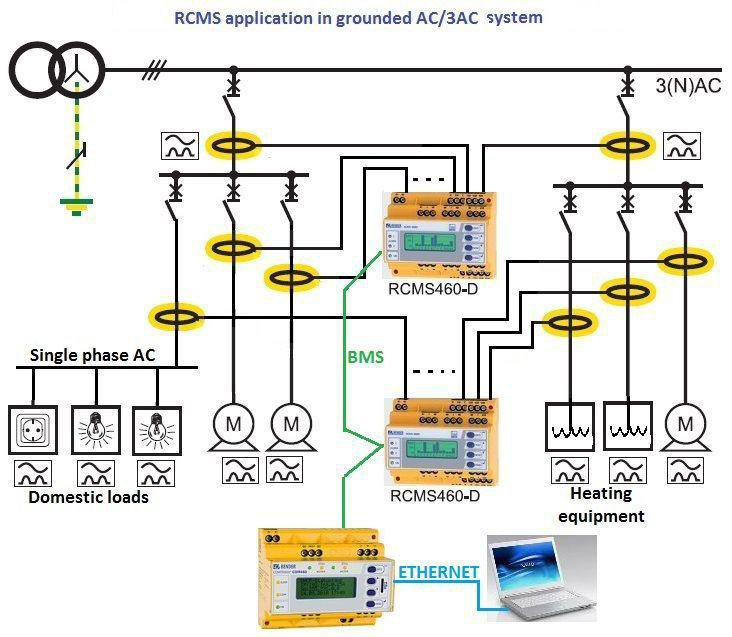

Online Residual Current monitoring with RCM to achieve improved plant availability and cost reduction in Grounded 3AC and AC System.

To be used where requires maximum possible availability and electrical safety for power supplies in industrial, residential and functional buildings.

|

• The insulation measurement is done via active measurement principle which employs injection of special bender patented AMPPLUS pulse

• The insulation monitor will measure the insulation resistance of complete galvanically connected system in real time and display its value in the backlit LC display. • Response values from 1 KΩ to 10 MΩ. • Nominal System Voltage AC,Dc or AC/DC up to 7.2 KV. • System Leakage capacitance up to 500 µF. • System Configurations 1Ph, 3Ph, disconnected loads. • Automatic Fault location with faulty feeder. • Automatically adapts to the system conditions and eliminates the effects of factors affecting accurate measurement such as Extraneous DC voltages, high and variable system leakage capacitances, variable low frequencies, harmonics etc. • Displaying information about the status of the electrical installation at a central location. • Remote diagnosis via internet/Ethernet. • All the Bender devices are in conformance to IEC 61557-8 and IEC 61557-9 and EMC qualified as per IEC 61326-2-4. |

To be used where requires maximum possible availability and electrical safety for power supplies in industrial, residential and functional buildings.

|

• Using TRUE RMS Principle to avoid any spurious alarms, for residual current measurement( upto 40th Harmonics) & detection True RMS measurement of leakage, works Universally from 0to 2000Hz. • Only predictive leakage Alarm and no tripping/shutdown of Loads. • Displays amount of current leaking in the system, Condition monitoring of Health of Motors/Drives. • Settings available above 5 mA. • Automatically locates the faulty feeders. • Microprocessor base relay with history memory, failsafe connection monitoring etc. • Increases production, reduces cost & planned, preventive maintenance. • In confirmation with IEC60364-4-41, IEC62020, IEC61557-6. |

|

|

|

|

• Multi-functional voltage relay for 3(N)AC systems, frequency/overvoltage/under voltage, phase, phase failure, asymmetry.

• Under voltage, overvoltage and frequency monitoring in 3(N)AC systems 0…500 V.

• Start-up delay, response delay and delay on release.

• Adjustable switching hysteresis,r.m.s. value measurement (AC+DC).

• Measured value memory for operating value, Continuous self monitoring, Internal test/reset button, Two separate alarm relays (one changeover contact each), N/C or N/O operation and fault memory behavior selectable.

• Undercurrent and over current monitoring in AC system with prealarm and main alarm or current monitoring with window discriminator function. Portable Earth fault Locator system for Grounded and Ungrounded System.

Portable insulation fault location systems for IT systems AC 0…790 V, 42…460 Hz/ DC 0…960 V or de-energized systems.

• Residual current measurement in TN/TT systems

• Use in main and control circuits, photovoltaic systems

• Locating current injectors PGH18… with variable locating current 1…25 mA

• Backlit LC display, 3 x 16 characters

• Works while systems is online or offline

Power Quality Analyzer and Energy Meter:

• Class A power analyser, certified accor¬ding to DIN EN 61000-4-30.

• Monitoring the quality of the voltage in accordance with DIN EN 50160.

• Communication :Modbus RTU and Modbus TCP.

• Inputs: 4 current inputs, 5 voltage inputs.

• Flicker measurement.

• Freely configurable recorders for waveform, consumption and long-term recording.

• Calculation of the total harmonic distortion THDU/THDI: harmonics up to the 63rd harmonic.

• Individual current/voltage harmonics.

• History memory for minimum and maximum values of current, voltage, energy, power rating etc. for each month.

• Accuracy class according to IEC 62053-22: 0.2 S.

Medical Isolation Panel for Group-2 Operation theatres and ICUs/ICCU/Premature Baby Room etc.. IT Power Supply Systems (Isolated Power Supply) are designed specifically for medical and surgical installations, so are more appropriate that an adapted industrial, commercial and domestic earthed (TN) supply systems.

The ensuing increased requirements for safe and secure power supply apply to all the electrical equipment used in hospitals and in particular for rooms like operating theatres, heart catheterisation rooms. High reliability and safety of electrical installations in this area means:

• ensuring high availability of electrical power supply

• selecting the appropriate protective measures against electric shock, particularly against electric shock under fault conditions

• creating a high level of electrical safety

The particular requirements of IEC 60364-7-710:2002 & Indian NEC-1985 apply to hospitals, private clinics, medical and dental practices, health care centres and dedicated medical rooms in the work place. It may be necessary to modify the existing electrical installation in accordance with this standard, when a change of utilization of the location occurs (e.g. intra-cardiac procedures). Medical locations are divided into 3 groups as per IEC-60364-7-710 considering the application of medical technical equipment on the patient. Group 0, Group 1 and Group 2.

|

|

There is no standard design of Bender TCP as each is designed to specific user requirements and individually manufactured to order. This may include functions specific to certain medical specialisms, services controls, IT screens and bespoke interlocks.

|

|